|

|

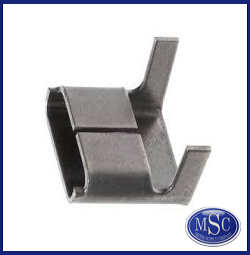

WING SEALS

ALUMINUM WING SEALS

Aluminum Wing Seals are manufactured from aluminum in .032" thickness to allow for maximum strength during tensioning. The wing seal is placed onto one end of a cut piece of strapping and is then used as the closure device for the strap. Aluminum Wing Seals are available in 1/2", and 3/4" widths.

|

STAINLESS STEEL WING SEALS

Stainless Steel Wing Seals are manufactured from heavy duty T-304 annealed stainless steel. These seals are .032" in thickness to allow for maximum tensioning and binding power. They are available in 1/2", and 3/4" widths. **T-316 available upon request.

*Both Aluminum and Stainless Steel Wings Seals are sold in boxes of 1,000 pieces.